STAFF CAR SAGAS

Matt finds time for a final push on his blown Minor

When is a car actually ‘finished’? Is it when you can drive it on the road? That first MOT? Or when the collection of parts in the shed dwindle to just those last curiously specific-looking washers? I ‘finished’ the restoration of my first car, the now-supercharged Morris Minor two-door saloon, midway through 2020.

I mean, that’s when I drove it for the first time, tentatively up and down the adjacent farm track. But plans for an epic road trip were scuppered by a virus, with travel restricted to the bare minimum and the weekly food shop seeming an inappropriately unnecessary contact risk should I break down on a test drive and require assistance or recovery. As the world found a new normal, I used the car a little more, and I did use it to drive my wife and I away from our wedding in 2021. But it was my now-sold MGB GT that whisked us to the Highlands on honeymoon – not this most precious of all my classics, as I had yet to grow to trust it fully. Since its ‘completion’, I’ve built and raced my Austin Seven special from the ground up, finished my epic Mini project (still for sale, incidentally) and even welcomed a new member to our family. But I’ve still never taken the Minor on a proper road trip, nor learned to fully trust it. Although it hadn’t completed many miles, I’d blown a differential to bits through slightly excessive use of the loud pedal, popped a head gasket towing a trailer to the NEC, suffered fuel starvation from a standard pump that couldn’t keep up with demand and been plagued by air leaks and potentially catastrophic lean-running (thankfully noticeable through the DTM Power air/fuel ratio meter I’d fitted).

A couple of months ago, I decided enough was enough, and removed the troublesome supercharger in favour a naturally aspirated set-up to get it mobile once more and allow me to fall in love with driving it again. And to make a list of the snags that needed resolving, belt-driven elephant in the room aside. The plan worked. I drove the car daily for a fortnight, even building myself up to trusting the car enough to take my daughter to nursery in it, and thoroughly enjoyed the heated leather seats now summer is a mere memory.

I adjusted all the brakes, played with tyre pressures and dialled in the fuel regulator such that it kept the carburettor brimmed without overcoming the seal of the float valve. A smile was glued to my face every moment behind the wheel.

Take charge

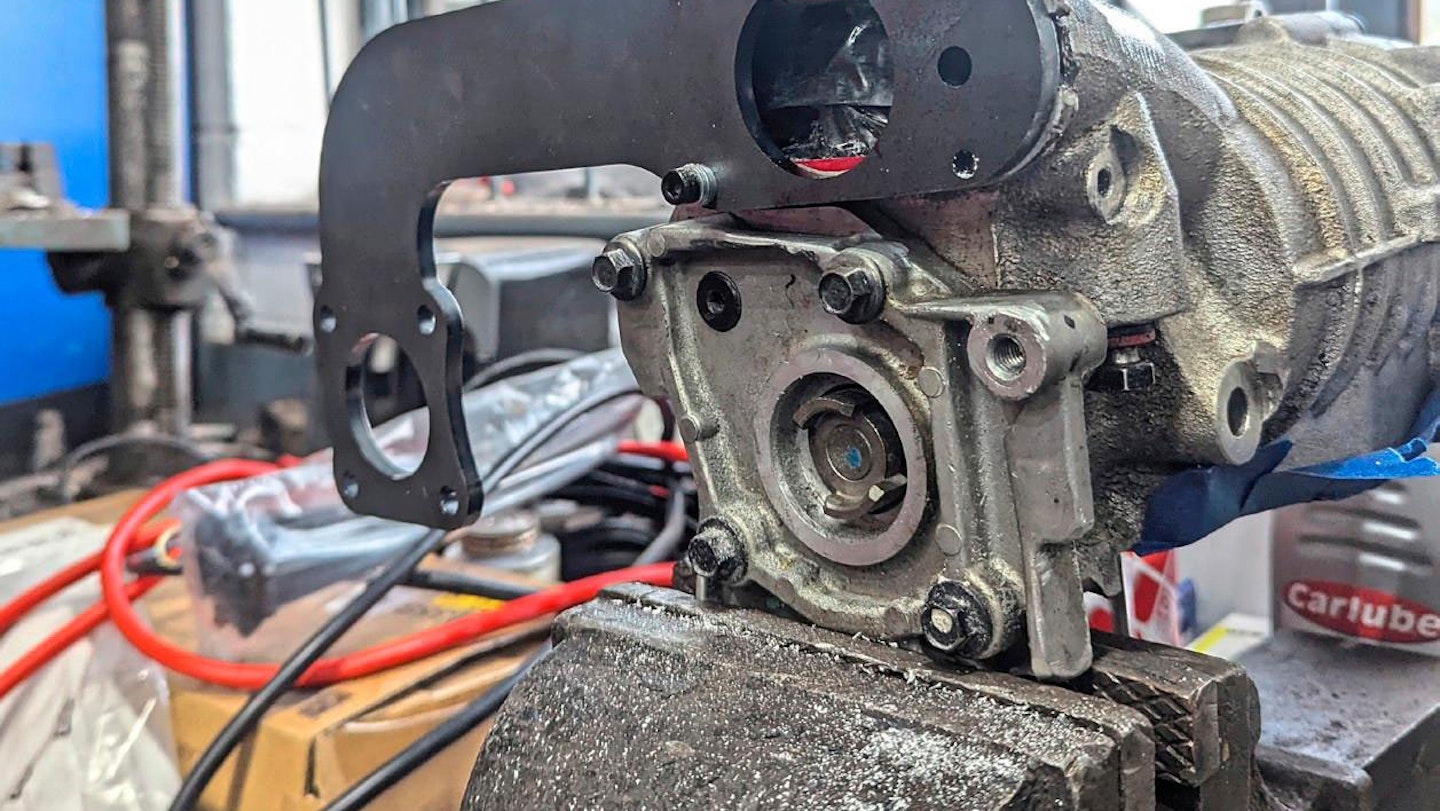

Meanwhile, the supercharger lay on the workbench, and plans were afoot. Since I first supercharged the car, a friend, Chris, had done the same to his Minor. But being a clever design engineer, instead of compromising on the original MINI mounting points as I had done, he had milled the back off of his supercharger and designed a neat inlet support plate on CAD, which bolted through four newly tapped holes on the induction side of the ‘charger, preventing the issue’s I’d faced with air leaks. With this concept proven on a trip to Belgium with his family, Chris kindly passed me the .DXT file, which I sent to a laser cutting firm. A week later, a plate arrived in the post that could be combined with a 180-degree 44mm mandrel bend from an online exhaust supplies shop to manufacture the cure to all my air leaks… I hoped. I headed for the PC workshop, called in Clive Jefferson for moral support and an additional pair of hands, and fired up the welder.

The first job was to modify the back of the ‘charger. I’d carefully removed the protrusion before the day in question using a hacksaw, file and a DA sander to finish the job, so it was now a case of using the newly-cut primary manifold plate as a drilling guide for four 4.5mm holes, which would be tapped to take M5 set screws. Pedants, don’t chastise me; the ‘charger is a modern part, so there’s no issue using metric fixings here! This was the scariest part of the job – there would be no going back if I broke through the alloy casting, but gently did it and soon the job was done. Next, Clive welded an M8 bolt to a pre-cut hole in the plate that Chris had designed in to allow a rose jointed rear support to be taken from the rearmost rocker cover bolt, before we set to work carefully cutting and measuring the pipework that would transfer the air/fuel mix from carburettor to supercharger.

Slicing the 180-degree bend through its centre gave us two identical bends that could then be marked, sliced and welded to the correct shape – with just enough clearance on the original fuel line and wiper motor to fit the ethos of easily reversible changes I’ve championed throughout this project.

Now with custom gaskets made, and plenty of compressed air deployed throughout to ensure no swarf had made its way into the pipework or ‘charger, it was ‘simply’ a case of building up the supercharger assembly as a package that could easily be removed and replaced with a NA setup should problems arise – can you tell I’m still unconvinced?!

Next steps

Sun set on the workshop with the ‘charge pack’ just bolted up, so there’s still some work to be done (drive belt, cables, hoses, braces etc) before I can turn the key and discover whether this was all work for nothing, and only then commence the long timing and tuning process to ensure the car can be safely driven without melting its expensive OMEGA pistons. However the end is now in sight and there's a deadline looming ever-closer. The car has a place on a rather special wintery road trip. Hundreds of miles await, and the clock is ticking. Find out what and where very soon in PC.

Subscribe to a PC Print+ Subscription today and you'll get instant digital access PLUS FREE UK delivery so you'll never miss an issue again. With our festive offer, try your first 6 issues for £19.99.