THE BIG RESTORATION

A restoration to factory spec was never on the agenda for speed freak Dean Harley and his bonkers Kawasaki-fied Fiat

WORDS MATT TOMKINS PICTURES MATT HOWELL

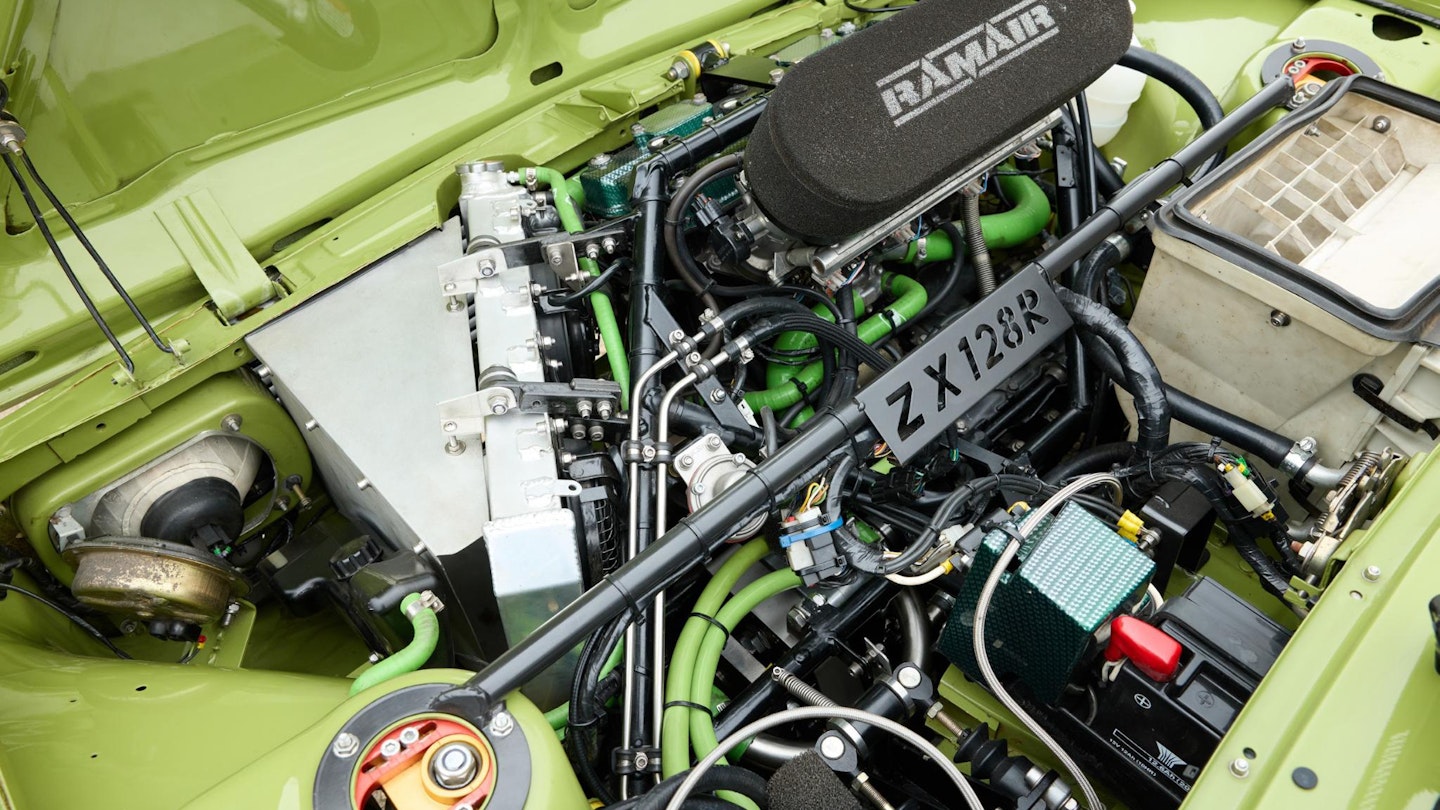

The first time I met Dean Harley, this Fiat 128 was in primer, on fire and had covered just three miles since rebuild into the spitting, snarling, bike-engined monster you see here. ‘Ahh, yes’, recalls Dean ‘I built the car up completely before sending it for paint and had come to the MOT bay opposite the PC workshop to have it tested.’ It had passed, but an electrical fault when the fans kicked in (Dean suspects a dodgy switch) sent then loom up in smoke. With the fire quickly extinguished, we bonded over a cuppa and a biscuit while he awaited recovery. Fast forward to today and the car before us is a true beauty, resplendent in a its original vibrant hue of Brilliant Green (Dean had one this colour as a lad). It has been meticulously applied, with the fit and finish of the extreme modifications incredibly well executed – and because the car had its ‘dry build’ before paint, there’s no compromise anywhere on the final painted surfaces.

Now powered by a Kawasaki ZX12R engine, the 128 had covered just 15,000 miles from new when Dean bought it. Purists may gasp, and I raise an eyebrow, but then Dean pulls a bent and twisted valve from the boot. ‘This was in the sump’ he grins. ‘The chap I bought it off had started it up after many years laid up without changing the cambelt, which snapped and lunched the engine.’ A lesson in how not to recommission a car. ‘Then, he’d towed it up his driveway but the rope snapped and rolled back into his house, caving in the rear panel and boot lid.’

This isn’t Dean’s first rodeo. A serial Fiat owner in his formative years, more recently he’s built two kit cars, a Tiger Super Sports and a Spire Sport GTR, the latter powered by the bike engine now fitted to his 128.

‘It took me a long time to bring myself to sell that,’ laments Dean, ‘but I couldn't finance the Fiat’s build without doing so, and I’ve only got a single garage. I was gutted back then, but now this is done I’m over it!’

It had taken Dean a great many years to find the 128 of his dreams, reminiscing of those cars he’d owned when he first felt the freedom of the driving seat. ‘Everyone else had Escorts and the like, but I was never one to follow the crowd. I had Fiats. They were different and I respected that.’ This one came along in 2011 via eBay and Dean recalls ‘it cost me more to get it home than my winning bid!’. It sat on his driveway for four years before he could bring himself to sell the kit car but, once it was in the garage, the engineering could commence. He began by manufacturing himself a 360-degree rotisserie onto which he mounted the 128 and set to work stripping it bare.

He had an end vision in mind, having ruminated on it and collected parts ever since the car arrived on the driveway. ‘I loved the bike engine in the kit car’ he recalls, ‘and the sequential six-speed gearbox just made the driving experience so special.’

‘I also knew, taking what I’d learned on the kit car, that I would be able to get the engine running properly outside of the bike.’ So that was the first big purchase, a Kawasaki ‘Ninja’ motorbike, a four-cylinder, 178bhp race-bred machine just out of MOT that had been dropped. ‘I love bikes,’ says Dean, ‘but I couldn't trust myself on one. This is the closest I’ll get to a motorbike these days.’

With that sort of power, however, he suspected that the shell would simply pull itself apart. ‘My son in law runs a local tool hire firm, so I was able to secure the use of a hydraulic pipe bender for the weekend.’ Just £70 secured Dean sufficient gas pipe to make himself a roll cage. ‘I tacked it all together then a work colleague, who’s a coded welder, did the pretty welding for me in exchange for me rewiring his garage,’ explains Dean. ‘The front is now securely tied into the rear of the car, holding the structure together as well as providing roll-over protection should the worst happen.’

You’ll no doubt have noticed that the car’s stance is non-standard. Dean made his own coil over suspension for the front, cutting the struts and removing 30mm from their height before having his work pal weld them back together to accept a set of KYB damper inserts for an early X1-9. At this point Dean pauses. ‘I’ve had so much help on this project from friends and colleagues who have been incredibly generous with their time and expertise. There are very few people I’d let work on this thing, so it’s testament to how much I think of those who have laid hands on it that they have done so to such an exceptional standard.’

With the struts shortened, Dean added rings top and bottom to hold the spring before moving to the rear, where he replaced the OE transverse leaf spring with a pair of aftermarket coil overs from Croatia. The distinctive wheelarches are also items that Dean sourced from Croatia, originally designed to fit a two-door model. He meticulously cut tabs in the original metalwork, bending them until they touched the glassfibre then infilling them to form an inner wheelarch that would allow the aftermarket alloys to sit ‘just so’. It’s barely noticeable but there’s some fabrication artistry going on at the bottom of the door too, which has been carefully re-shaped to allow the arch profile to be retained without compromise. Dean is modest but it’s clear that there has been an incredible amount of work done here. This was all done at the same time as unpicking the damaged rear panel and replacing it, along with the boot lid, to ensure a perfectly solid shell to build on.

Braking is expertly devised too. ‘I took a full front hub to Rally Design, who helped me to work out the setup.’ Dean explains. It uses Fiat Punto HGT front and rear discs with a balance bar on the master cylinder. Willwood four-pot front callipers and Punto rears help to arrest the momentum that was to come with the Kawasaki engine.

Dean bought a blown up ‘Ninja’ engine for mocking up purposes, allowing him to strip it bare and ensure minimal strain on his back during the man hours of trial fitting. ‘I built a subframe that accepts the engine, gearbox, sprocket and separate reverse 'box,’ explains Dean. ‘I made it out of conduit first before re-making it in CDS, tacking it together and once again passing the job of the pretty welding to my friend.’ Once the ‘real’ engine from Dean's donor bike was in the frame, the electrical work could start. As with any modern engine transplant, there’s a significant amount of work to be done to ensure the ECU doesn’t go into meltdown, however taking everything he’d learned from the Spire Sport, Dean was able to unpick the original harness and build a complete new wiring loom which would run both engine and car. He’s even been able to extricate the bike’s gauges and seamlessly integrate them into the Fiat’s dashboard. It’s all very impressive.

By March 2020, the Fiat was running and moving under its own power. Just before the world went into lockdown, Dean took the car for its MOT, which is where this tale began. Once the fan wiring issues had been resolved, the car was on the road, working, functioning – doing car things – but like so many of us, the lockdown period gave Dean time to tinker. By April 2021 the car was a bare shell once more, stripped of every last component and sent to Envirostrip to be chemically dipped and stripped back to bare metal.

Back it came and into a local paint shop to receive its gleaming coats. ‘I’m a perfectionist’ admits Dean, ‘and I knew that if I did the bodywork myself I wouldn’t never be happy with it. Andrew Bateson, who runs a local bodyshop specialising in mainly dents and minor crash repairs, came highly recommended. He wasn’t keen on painting a whole car at first but I managed to persuade him to take it on.’ I’m sure you’ll agree, the result is truly spectacular – a finish befitting of the engineering genius underpinning it all.

‘It’s definitely not to everyone’s taste,’ Dean laughs ‘but I built it for me, not for anyone else – and I love it.’ I must admit, I love it, too – as does Dean’s stepdaughter, Emily, who describes it as a ‘Feral Fiat’. I can’t think of a better description.

ACA BOSS LYN SAYS...

‘Radical is the word. Some revivals are more extreme than others, but what Dean has done is based on sound engineering. Alan's XR2 is just as jaw droppiung though. A meticulous revival, from scrapyard to concours.’

Subscribe to a PC Print+ Subscription today and you'll get instant digital access PLUS FREE UK delivery so you'll never miss an issue again. Check out our offers today.