THE BIG RESTORATION

Magic happened when Phil Smith and best pal Ray Preston joined forces…

WORDS JAMES WALSHE PICTURES MATT RICHARDSON

A humble chap, is our Phil. ‘I’ve been trying to work out if I have any skills.’ Standing beside his Triumph in the garage he built himself, he begins our day together deflecting much of the praise towards his best mate, Ray Preston. ‘Ray is a proper car restorer. He does everything. I just make the tea’. Ray chips in to confirm this, but with a wink. ‘He’s very good at fetching spanners’. Truth is, they’re both fibbing.

Phil was no mere casual observer in the revival of what began as an extremely rotten workhorse. He and fellow 2000 Register member in Kent, Charles Harrison, saved the car in 2016 and managed to get it back on the road for use as a daily driver, Phil ragging it around motorsport events such as the Blackpalfrey Motor Club’s Hughes Rally. ‘As time went by, I had the feeling the corrosion underneath was serious enough for me to take it off the road for good.’ With help from another mate, experienced bodywork guru Ray, they decided to investigate and… ‘Well, we got a bit of a shock!’ says Phil. Underneath the Triumph’s French Blue paintwork lay some genuine horror. ‘The sills were in such poor condition, it was clear the fragile old thing wouldn’t survive being jacked up in order to fit it to the rotisserie’.

It soon dawned on him that doing the work alone was unthinkable. ‘It felt just too daunting, which is where your mates come into it. Ray assured me it could be fixed and we made the decision to work together.’ However, before they could start, Phil needed to make some modifications to his house. He designed and built himself a covered area on the end of the building, where he and Ray could work on the Triumph irrespective of poor weather. Later, irritated by the cold wintry breezes rushing through the area, Phil added a wall and some doors. ‘It meant working without freezing our bums off was now possible.’

As work commenced, the decision was made to replace the sills with the car still on the ground, so with steel bars welded between the doors the inner, middle and outer sills were cut out with the angle grinder. Phil says the fitment of the bars improved things no end. ‘It was considerably stronger than before, and a trial fit of the doors confirmed everything was where it should be.’

Engine and gearbox removed, along with the interior, Phil and Ray lifted the body onto the rotisserie. ‘The quality of this one was great and with the hydraulic rams easy to get the car high enough to work on’. Ray chips in. ‘I’ve had replacement knees and have back problems, so not having to lie on the ground was handy!’ The stripping of the body continued and bit by bit, the car began to disappear before Phil’s eyes. ‘As I hacked away at the sills, it got worse,' he explains. 'Any vibration would result in another great big pile of rust forming on the floor!’

Here’s how they did it…

1 AUG 2022

Working as a team, Phil and Ray stripped the car, fabricated, welded and lead loaded –from the wings and to the rotten sills and boot floor.

2 OCT 2022

As the weather cooled, Phil became more aware of the exposed part of his home-built work area, so he began building a wall that would seal this area from those wintry drafts!

3 NOV 2022

The windscreen surround was rotten. After much cutting, hammering and welding the holes were filled with lead and readied for finishing.

4 DEC 2022

Ray’s skills with lead meant filler could be mostly avoided but a thin skim was applied for a good finish. Phil’s mission was to keep the dust out of the house!

5 OCT 2023

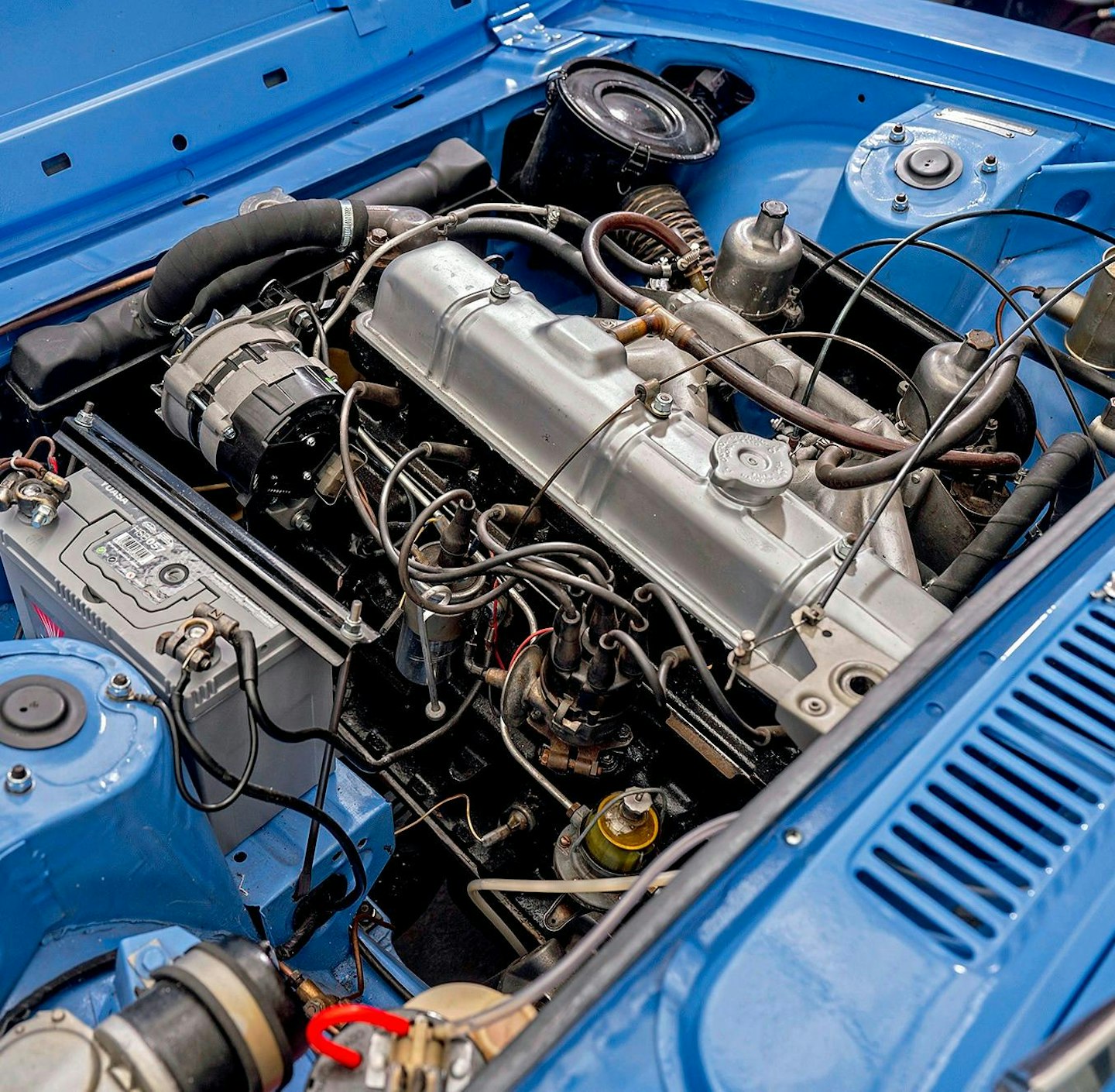

After delays and injury, the previously smoky engine was rebuilt. The pair found evidence of mildly worn bearings top and bottom, while measuring the bores revealed piston wear.

Helping hands

Phil admits that he’s no bodywork expert. ‘Some of the welding was complex and beyond anything I’d be capable of, so that’s where friendship really counts! I concentrated on stripping, cleaning, de-rusting, sanding and stripping the paintwork while Ray worked his magic on those tricker areas of bodywork. It made sense – there’s no point in going to all this effort and not making it the best it can be.’ Sipping on his tea, an ever-humble Ray shrugs. ‘As with anything, you must work to the best of your strengths’. In a previous life, Ray worked for the former British Leyland dealer Martin-Walter in Kent – a company that established itself in 1773 by making harnesses and (much) later building bespoke car bodies.

‘I started there at the age of 16, working as a panel beater and coach builder in the body shop and learned skills suitable for repairing Jaguars, Armstrong Siddeley, Roll-Royces and Bentleys.

I think Phil reckoned lead loading the Triumph would be a piece of cake. It wasn’t!’

With Ray lead loading on one side of the car and Phil stripping the paint on the other, Phil says they continually came up against obstacles. ‘For instance, a significant dent appeared through layers of filler as I removed the paint, while spiders of rust and holes appeared all over the place.’ He had become very well acquainted with repair panels from Lloyd Reed at South Wales Triumphs, with items arriving as funds permitted. ‘Without Lloyd it feels like we’d have been here for years!’

When the pair got to the nearside front wheelarch, they found a fair bit of work was needed to replace the inner bowl, the front section ahead of the arch and the bottom of the wing. Removal would be necessary anyway in order to fit the sills and wheelarch – the latter of which had been cut from a scrap car years ago and kindly provided by aforementioned friend Charles. ‘Making sure all these four sections all came together properly involved a load of trial fitting, tack welding and jiggling before we were happy’.

Another parcel from Lloyd meant they could now set to work on sorting the rear wheelarch, while the boot floor got the attention it needed. ‘Rather than weld in loads of little patches, we decided to cut a large section out and replace with one larger piece of metal. Again, much cutting, bending and hammering was required!’

By now, the pair were into the swing of things. Phil says the condition of the windscreen surround was, predictably, poor. After much cutting bending hammering and welding the holes were filled, lead added and reshaped ready for finishing, the chaps now ready for the next stage, which was to add the primer and seam sealer.

That was until Ray, on his way to celebrate his own 70th birthday, slipped over and broke his hip.

The final leg

As Ray’s injuries healed, Phil got started with the dull job of rubbing down the car’s body to get a satisfactory surface. He then had a crack at the cabin. ‘My father was into woodwork, so I learned a lot from him. I stripped and veneered all the Triumph’s wood and was happy with the result. I couldn’t wait to see it on the car!’ One of the highlights for Phil came after a two-week holiday with his wife Clare. ‘We came back to find Ray and his son Adam had painted the car. I was speechless – it looked fantastic!’

Phil and Ray then rebuilt the doors and refitted the glass new rubbers and seals, along with exterior trim and lights. Underneath, with the cleaned and painted suspension components refitted – the brakes followed with new pipes all round and rebuilt calipers – it was time to sort the engine. Having stripped it and replaced the bearings and pistons, the valves were removed, cleaned up and reground to the head. ‘Examining the radiator we found it to be badly corroded, so a trip to Regal Rads in Maidstone was needed. While we waited for the rad, we worked on the heater, fitting a new valve.’ Talking of interior comfort, Phil rewired areas of the car including the stereo, while the carpets were refitted, along with new boot boards and headlining – the latter of which was a particularly awkward job. ‘The headlining was such a fiddle – it took a lot of persuasion and swearing.’

ACA BOSS LYN SAYS…

‘Two hugely contrasting restos this issue. The team effort on the Leyland bus is a true labour of love and one shared by volunteers. All credit to them. And this Triumph… well, what a job, considering the state it was in. ’

When the time came to fire up the engine, Phil was dismayed to find the clutch was solid. ‘There was much worrying that we hadn’t fitted the clutch correctly; we didn’t want to have to remove the gearbox at this point. However, we were relieved to find the slave cylinder had seized, so a replacement was duly fitted.’ Take two!

Phil says the time hd come at last... ‘One day, we looked at each other and agreed there was nothing more to do. A careful drive around the block to check for further niggles went so well, we drove a bit further and put some petrol in the tank for a trip to a breakfast meet in Dungeness.’

However, Phil admits that ten minutes into the first big trip, to a 2000 Register event to Norfolk, the diff went bang. 'They're never truly finished, are they?' Phil says he’ll get around to sorting the rest out soon enough. ‘The bumpers are tatty, the seats are worn and the clock doesn’t work. Replacing these pushed the restoration beyond what I could budget for, so they will have to wait. The fact it isn’t completely immaculate means I can use it and enjoy it. I mean, given the terrible rust, in hindsight we probably wouldn’t have even started it, so it’s a miracle it’s here at all!’

Subscribe to a PC Print+ Subscription today and you'll get instant digital access PLUS FREE UK delivery so you'll never miss an issue again. With our festive offer, try your first 6 issues for £19.99.